Environment, social and governance (ESG) considerations play increasingly crucial roles in a company’s prospects and viability. Key stakeholders, including consumers, investors, regulators and non-government organizations, are taxing that companies incorporate ESG factors into nearly every speciality of their merchantry strategy and operations, from procurement and manufacturing through to product minutiae and hiring.

As a global leader in information technology with 30 production sites worldwide, LG Electronics has recognized that for ESG management to be constructive it needs to be integrated into a company’s day-to-day operations.

In 2018, the visitor outlined its strategic direction for ESG management based on standards required by the international community, which reflected the Sustainable Minutiae Goals established by the United Nations. After reviewing its ESG performance over the previous three years, the visitor established a new direction for its ESG program and, in 2022, launched The Largest Life Plan 2030.

The Largest Life Plan 2030 includes six ESG commitments, three of which aim to significantly modernize the company’s environmental performance by reducing its greenhouse gas (GHG) emissions and increasing the use of recycled materials in its products. For example, LG has single-minded to rhadamanthine stat neutral by 2030 by reducing emissions generated from its production processes. To unzip this, the visitor plans to reduce by 50 percent the 1.93 million tons of stat dioxide equivalent (tCO2e) generated in 2017 by creating increasingly energy-efficient facilities and raising emission reduction technologies.

LG Smart Park

To support its carbon-neutrality goals, the visitor has transformed its factory complex, in Changwon, South Korea, into a futuristic manufacturing hub for its home appliances line. Renamed the LG Smart Park, the ramified uses a digitally enabled 3D logistics system, wide whet computing and machine learning analytics to predict defects, and state-of-the-art facilities to produce multiple models that respond to consumer requirements.

Earlier this year, the World Economic Forum (WEF) selected the ramified as a Lighthouse Factory – these showcase companies that demonstrate leadership in using Fourth Industrial Revolution technologies. LG Smart Park has increased productivity by 17 percent and reduced the forfeit of defective-product returns by 70 percent. The factory has reduced GHG emissions and boosted energy efficiency per unit produced by 30 percent compared to an older site. The visitor plans to wield the smart production technologies pioneered at LG Smart Park to 26 of its production facilities in 30 countries, progressive the digital transformation of its global manufacturing network by 2025.

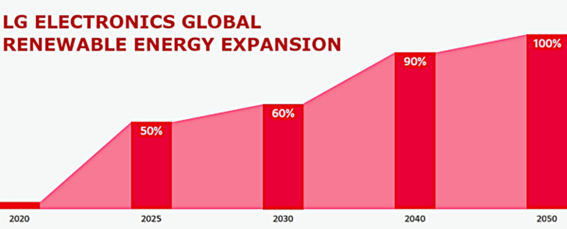

The remining 960,000 tCO2e generated in 2017 will be offset by securing stat credits through the United Nations Framework Convention on Climate Change’s Clean Minutiae Mechanism, which allows it to reduce emissions by investing in technology and wanted in developing countries, and through external stat reduction activities by utilizing its high-efficiency home appliances. And, under the ESG framework, the visitor aims to source 60 percent of its energy from renewable technologies by 2030, transitioning to 100 percent renewable energy by 2050.

LG is moreover single-minded to towers a circular economy through waste recycling initiatives and improving waste treatment processes and aims to recycle 95 percent of waste generated at its global production sites by 2030, up from 92 percent in 2021, by utilizing 600,000 tons of recycled plastics in its manufacturing processes.

“Conducting product stability and quality reliability tests will modernize resource efficiency, with recycled materials stuff used in a range of products, from washing machines and refrigerators to air conditioners and TVs,” say Hong Sung-min, throne of LG’s ESG department. “LG is moreover implementing policies to comply with regional regulations on the take-back and disposal of e-waste by establishing infrastructure for the recovery of e-waste.”

LG Chilseo Recycling Center

To support its efforts, the visitor opened the Chilseo Recyling Center, in South Korea, in August 2001. “The facility is spearheading the company’s e-waste initiative by collecting electronic waste at the end of product lifecycles and re-using recycled plastic to manufacture new components for use in home appliances like refrigerators,” adds Hong.

LG is moreover improving the energy performance of its products. Older this year, the visitor launched its new ThinQ washing machine, which features an Artificial Intelligent Direct Drive (AI DD) motor, which uses deep learning to identify variegated types of fabrics and then selects the optimal trundling and settings for each load. In a first for the home utilization industry, the AI technology unromantic to the upgradable utilization laundry solutions received the AI Algorithm Reproducibility Process Verification from UL, a global safety science leader, which helps companies to demonstrate safety, enhance sustainability and unzip regulatory compliance.

“LG’s current activities are in line with our mid- to long-term ESG strategy to produce eco-friendly products and services for future generations,” says William Cho, CEO of LG Electronics. “LG is urgently working on environmental solutions, so that future generations can enjoy a largest life and contribute to a largest tomorrow.”

This story was edited from an editorial full-length vendible published in Nature magazine.

# # #